How To Fix P0019? | Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor B)

When you purchase through links on our site, we may earn an affiliate commission. See our affiliate disclaimer for more information.

What does the P0019 Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor B) mean?

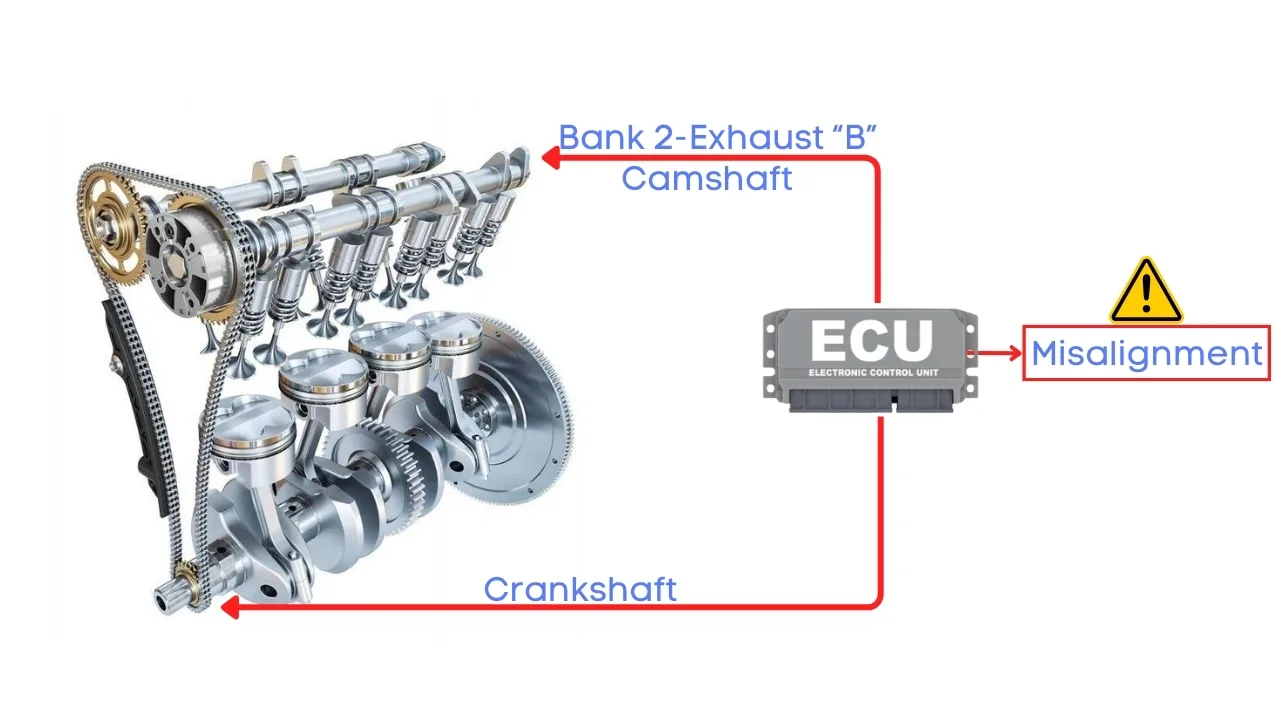

The P0019 code indicates that the ECM has detected a correlation error between the camshaft position sensor for Bank 2, specifically the exhaust camshaft, and the crankshaft position sensor. This means there’s a misalignment between the camshaft and crankshaft positions.

When the P0019 Triggers?

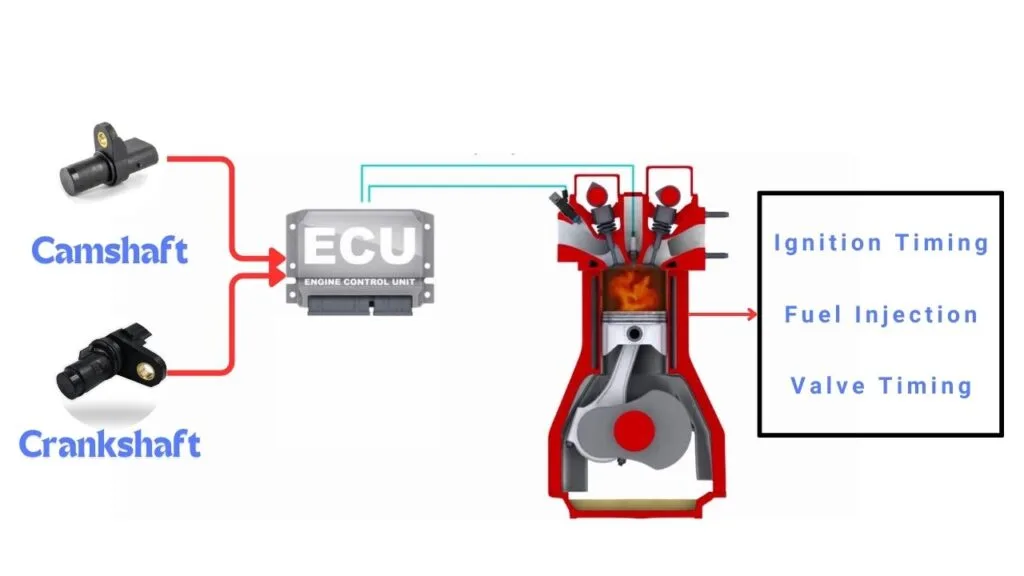

The camshaft position sensor measures the position of the camshaft, while the crankshaft position sensor measures the position of the crankshaft. Both of these sensors send crucial data to the ECM, which uses this information to control ignition timing, fuel injection timing, and valve timing.

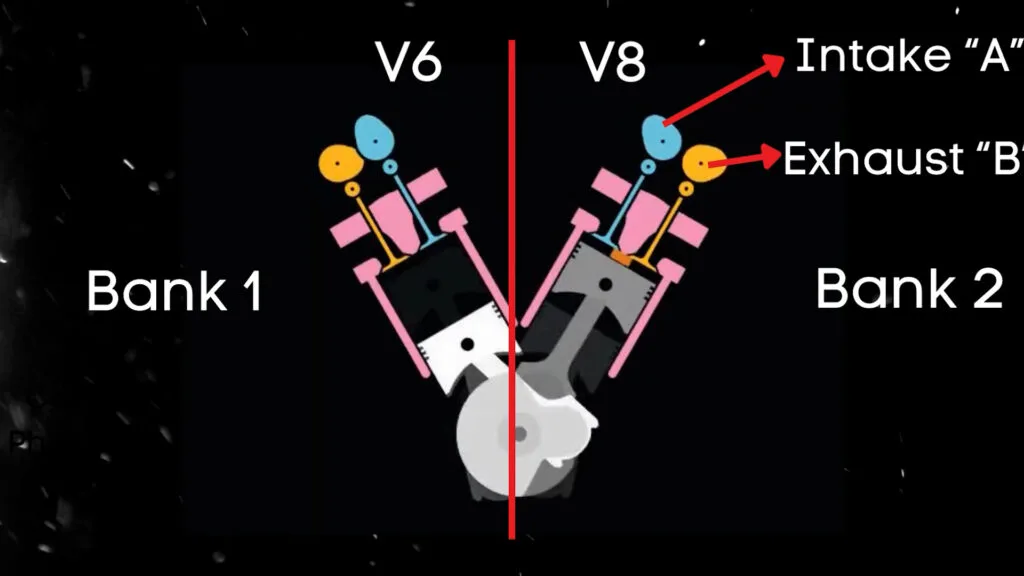

In the case of V6 or V8 engines, there are two camshafts: Bank 1 and Bank 2. For Dual Overhead Camshaft (DOHC) engines, there are two camshafts per bank: intake and exhaust.

When the ECU detects that the Bank 2 exhaust camshaft position and crankshaft position are out of sync by a specific degree, it triggers the P0019 code.

How To Fix P0019?

Troubleshooting P0019 involves several steps, and we’ll discuss each one in detail. Let’s get started!

Before diving into specific repairs, perform an OBD-II scanner reset to clear the codes. Sometimes, these codes pop up due to recent maintenance work and can resolve themselves after a reset.

To reset the error codes, use an OBD-II scanner. Simply connect the scanner to your vehicle, follow the instructions to clear the trouble codes, and see if the P0019 code reappears.

If the code comes back, it means there’s a persistent issue that needs further troubleshooting.

Step #1 – Scan for any other activated OBD-II codes.

The first step is to scan for any other activated OBD-II codes. This helps us pinpoint where we need to focus. If there are other codes related to a faulty camshaft sensor, we should focus on the camshaft sensor. Similarly, if there are codes related to the crankshaft sensor, that’s where our attention should go.

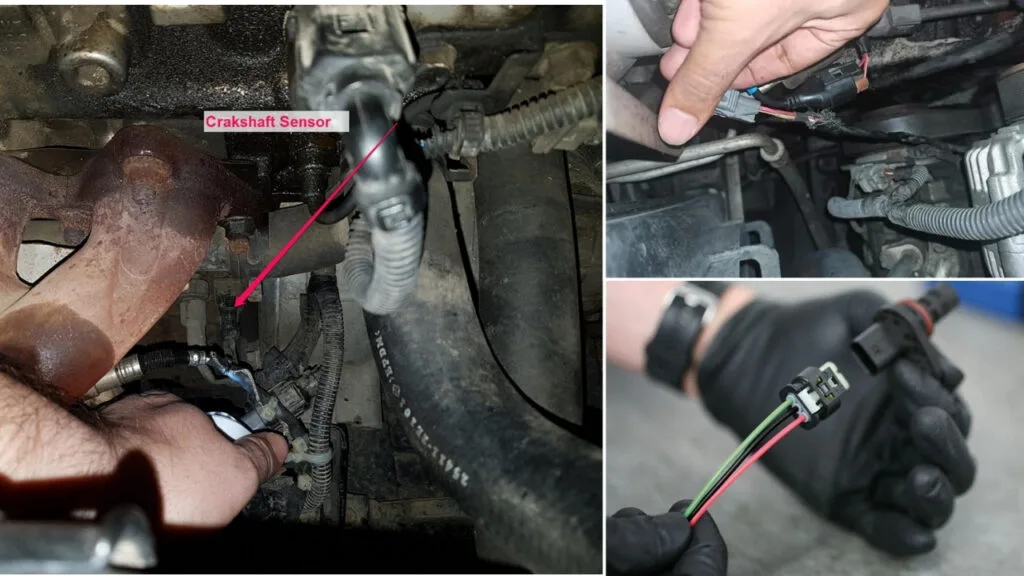

Step #2 – Visually Inspect Cam and Crank Sensors

Visually inspect the cam and crank sensors and their harnesses for damage. Look for broken or frayed wires. If you find any, repair them and recheck. If the crank and cam sensors are physically damaged, they need to be replaced. If both the crank and cam sensors, along with their harnesses, are in good condition but the P0019 code still persists, further troubleshooting is required.

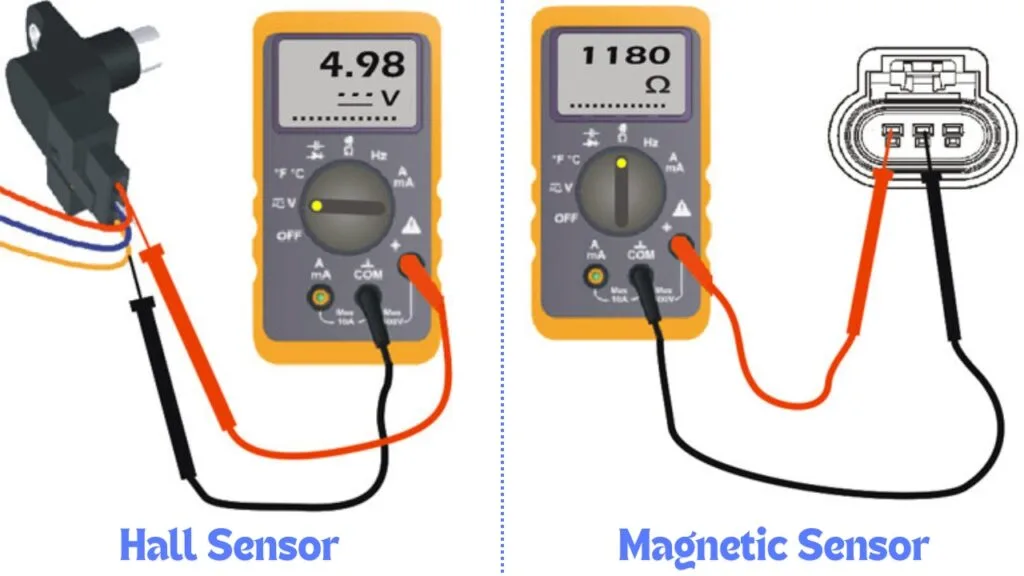

Step #3 – Test Crank and Cam Sensors

You can test the crank and cam sensors using a multimeter. However, the testing method varies depending on whether you have a Hall Effect sensor or a permanent magnetic sensor.

If both the crank and cam sensors test okay, it’s time to move on to the next step.

If both the crank and cam sensors test okay, it’s time to move on to the next step.

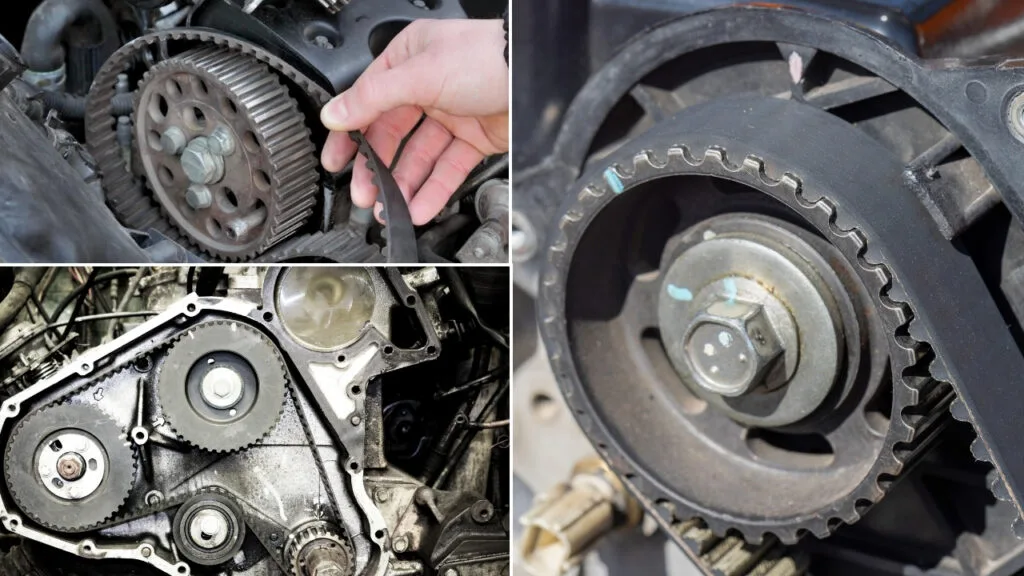

Step #4 – Visually Inspect Timing Belt or Chain

What ties the camshaft and crankshaft together is the timing belt or chain. Check that the belt or chain isn’t stretched. Also, check for a damaged tensioner that may have allowed the chain or belt to slip a tooth or several teeth.

If everything with the timing belt or chain looks okay and there’s no sign of stretching or damage, we need to move to the next step.

Step #5 – Check Tone Ring

The last suspect is the tone ring. Remove the cam gear and the crankshaft harmonic balancer and inspect the tone rings for proper alignment. Make sure they’re not loose or damaged, and check that they haven’t sheared the key that aligns them.

If the tone rings are misaligned, damaged, or have a sheared key, they need to be fixed or replaced to fix P0019