Arctic Cat Fault Code List | Trouble Code | OBD Code | DTC Code

When you purchase through links on our site, we may earn an affiliate commission. See our affiliate disclaimer for more information.

Arctic Cat OBD-II Fault Codes List

Here is a list of standard diagnostic trouble codes (DTCs) used by Arctic Cat, to identify vehicle problems:

- P0XXX: Generic Powertrain Codes

- P1XXX: Arctic Cat Specific Codes

- P2XXX & P3XXX: Generic Codes

- BXXXX: Body Codes

- CXXXX: Chassis Codes

- UXXXX: Network Codes

Read more about:

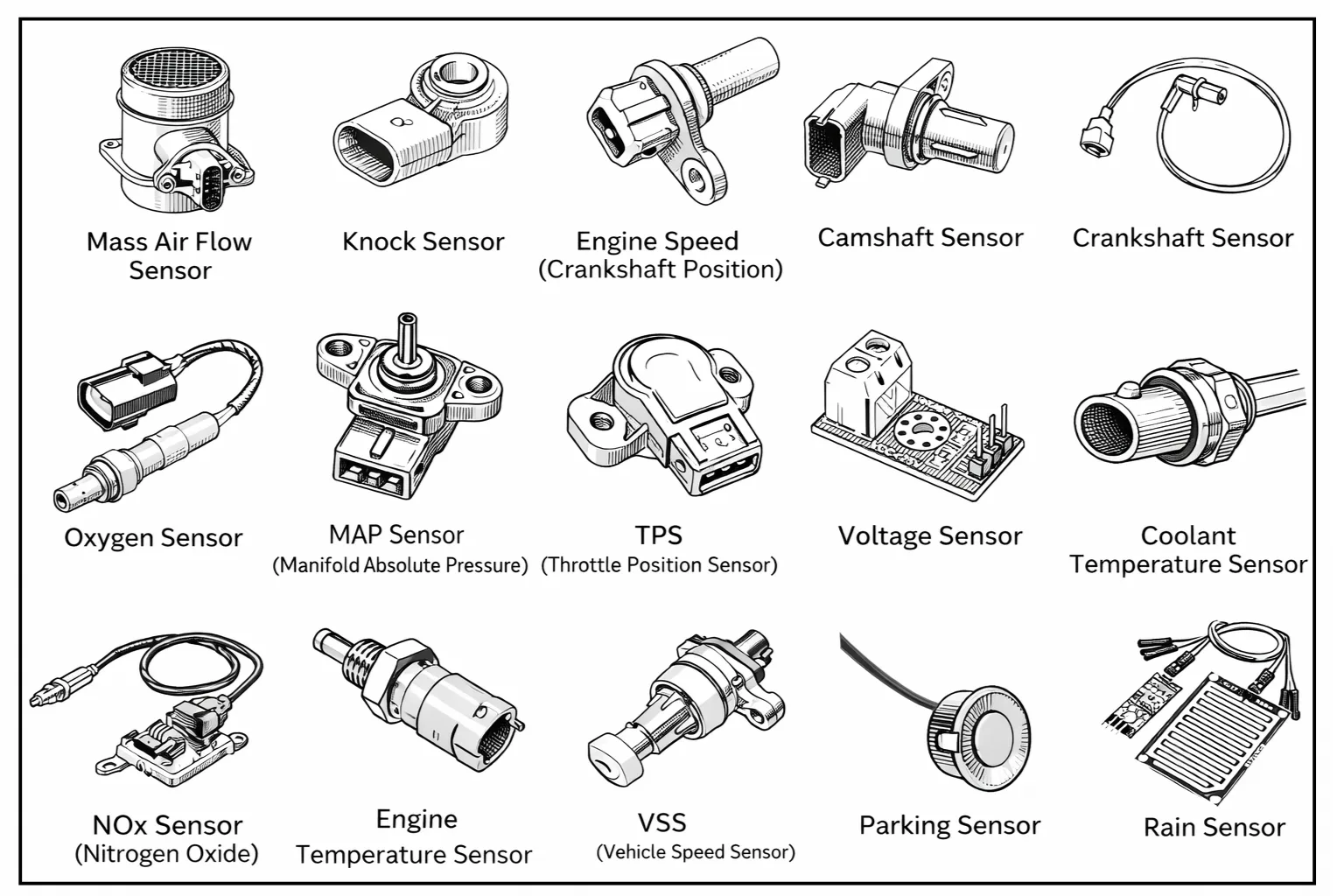

Car Sensors Explained: What They Do and How to Diagnose Them

With the increasing use of electronic systems in modern vehicles,…

This code list has been prepared after thorough research and from authentic sources [1].

| OBD Code | Fault | Descriptions |

|---|---|---|

| C0063 | Tilt Sensor Circuit High | The ECM has detected a high voltage condition on the tilt sensor circuit input. It is possible the tilt sensor or its interconnect harness is shorted to battery power. To clear the fault code, correct the tilt sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| C0064 | Tilt Sensor Circuit Low/SG/Open | The ECM has detected a low voltage condition on the tilt sensor circuit input. It is possible the tilt sensor or its interconnect harness is shorted to chassis ground or it has an open circuit. To clear the fault code, correct the tilt sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| C1263 | Backup/Reverse Light Circuit Open | The ECM has detected a low voltage condition on the tilt sensor circuit input. It is possible the tilt sensor or its interconnect harness is shorted to chassis ground or it has an open circuit. To clear the fault code, correct the tilt sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| C1264 | Backup/Reverse Light Circuit High | A high voltage condition has been detected on the backup/reverse-light circuit output. It is possible the backup/reverse-light or its interconnect harness is shorted to battery power. To clear the fault code, correct the backup/reverse light circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| C1265 | Backup/Reverse Light Circuit Low/SG | A low voltage condition has been detected on the backup/reverse-light circuit output. It is possible the backup/reverse-light or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the backup/reverse light circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0016 | Crankshaft Position – Camshaft Position Correlation | The ECM has detected an error in the camshaft position signal timing based on the synchronization of the crankshaft position sensor. It is possible the engine is timed incorrectly or there is an issue with either the camshaft position sensor or crankshaft position sensor. To clear the fault code, correct the crankshaft position – camshaft position correlation condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0030 | O2 Heater Intermittent/Open | The ECM has detected an intermittent or open circuit condition on the O2 heater output. It is possible the O2 heater or interconnect harness is open or is producing an intermittent voltage. To clear the fault code, correct the O2 heater circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0031 | O2 Heater Low/SG | The ECM has detected a low voltage condition on the O2 heater output. It is possible the O2 heater or interconnect harness is shorted to chassis ground. To clear the fault code, correct the O2 heater circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0032 | O2 Heater High/SP | The ECM has detected a high voltage condition on the O2 heater output. It is possible the O2 heater or interconnect harness is shorted to battery power. To clear the fault code, correct the O2 heater circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0034 | Turbocharger Bypass Valve Control Circuit Low | A low voltage condition has been detected on the turbocharger bypass valve control input. It is possible the turbocharger bypass valve relay or its interconnect harness is open or shorted to ground. Correct the turbocharger bypass valve control circuit low malfunction and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0035 | Turbocharger Bypass Valve Control Circuit High | A high voltage condition has been detected on the turbocharger bypass valve control input. It is possible the turbocharger bypass valve relay or its interconnect harness is shorted to power. Correct the turbocharger bypass valve control circuit high malfunction and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0107 | MAP Circuit Low/SG/Open | A low voltage condition has been detected on the manifold absolute pressure sensor input. It is possible the MAP sensor or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the MAP sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0108 | Manifold Absolute Pressure Circuit High | A high voltage condition has been detected on the manifold absolute pressure sensor input. It is possible the MAP sensor or its interconnect harness is shorted to battery power. To clear the fault code, correct the MAP sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0112 | Intake Air Temperature Sensor Circuit Low | A low voltage condition has been detected on the intake air temperature sensor input. It is possible the intake air temperature sensor or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the intake air temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position or restart the engine. |

| P0113 | Intake Air Temperature Sensor Circuit High | A high voltage condition has been detected on the intake air temperature sensor input. It is possible the intake air temperature sensor or its interconnect harness is open or shorted to battery power/regulated voltage. To clear the fault code, correct the intake air temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position or restart the engine. |

| P0114 | Intake Air Temperature Sensor Circuit Intermittent | The ECM has detected an intermittent voltage condition on the IAT sensor input. It is possible the IAT sensor or interconnect harness is damaged causing an intermittent voltage. To clear the fault code, correct the IAT sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0115 | Engine Coolant Temperature Sensor 1 Circuit | A constant voltage condition has been detected on the engine coolant temperature sensor input. It is possible the engine coolant temperature sensor is faulty or the thermostat may be stuck. To clear the fault code, correct the engine coolant temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0116 | Engine Coolant Temperature Sensor Circuit Range/Performance | The ECM has detected the engine coolant temperature sensor input is out of range. It is possible the engine coolant temperature sensor or interconnect harness is causing the signal to be out of the normal operating range of the sensor. To clear the fault code, correct the engine coolant temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0117 | ECT Sensor Circuit Low/SG | A low voltage condition has been detected on the engine coolant temperature sensor input. It is possible the engine coolant temperature sensor or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the engine coolant temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0118 | ECT Sensor Circuit High/Open/SP | A high voltage condition has been detected on the engine coolant temperature sensor input. It is possible the engine coolant temperature sensor or its interconnect harness is open or shorted to battery power. To clear the fault code, correct the engine coolant temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0119 | Engine Coolant Temperature Sensor Circuit Intermittent | The ECM has detected an intermittent voltage condition on the engine coolant temperature sensor input. It is possible the engine coolant temperature sensor or interconnect harness is damaged causing an intermittent signal. To clear the fault code, correct the engine coolant temperature sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0120 | Throttle Position Sensor Circuit | This code will be set any time an error has occurred in the TPS circuit. The TPS or its interconnect harness is open, shorted to ground or shorted to battery power. To clear the fault code correct the TPS circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0121 | Throttle Position Sensor Circuit Range/Performance | The ECM has detected the TPS input is out of range. It is possible the TPS or its interconnect harness is causing the signal to be out of the normal operating range of the sensor. To clear the fault code correct the TPS circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0122 | TPS Circuit Low/SG | A low voltage condition has been detected on the throttle position sensor input. It is possible the throttle position sensor or its interconnect harness is shorted to chassis ground. To clear the fault code correct the throttle position sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0123 | TPS Circuit High | A high voltage condition has been detected on the throttle position sensor input. It is possible the throttle position sensor or its interconnect harness is open or shorted to battery power. To clear the fault code correct the throttle position sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0130 | O2 Sensor Circuit | An intermittent open or open circuit condition has been detected on the O2 sensor input. It is possible that the O2 sensor or its interconnect harness have an intermittent open or an open circuit. To clear the fault code correct the O2 sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0131 | O2 Sensor Circuit Low | A low voltage condition has been detected on the O2 sensor input. It is possible the O2 sensor or its interconnect harness is shorted to chassis ground or an air leak may exist in the exhaust. To clear the fault code correct the O2 sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0132 | O2 Sensor Circuit High | A high voltage condition has been detected on the O2 sensor input. It is possible the O2 sensor or its interconnect harness is shorted to battery power. To clear the fault code correct the O2 sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0171 | System Too Lean | The ECM internal O2 feedback is lower than expected. It is possible that this symptom is caused by low fuel pressure, dirty fuel filter or dirty injectors. To clear the fault code correct the lean condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0172 | System Too Rich | The ECM internal O2 feedback is higher than expected. It is possible that this symptom is caused by excessive fuel pressure, faulty MAP sensor or faulty temp sensors. To clear the fault code correct the rich condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0201 | Injector Circuit/Open Cylinder 1 | An intermittent open or open circuit condition has been detected on the fuel injector circuit, PTO side cylinder. It is possible that the injector or its interconnect harness have an intermittent open or an open circuit. To clear the fault code correct the injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0202 | Injector Circuit/Open Cylinder 2 | An intermittent open or open circuit condition has been detected on the fuel injector circuit, center cylinder on 7000, MAG cylinder on 3000. It is possible that the injector or its interconnect harness have an intermittent open or an open circuit. To clear the fault code correct the injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0203 | Injector Circuit/Open Cylinder 3 | An intermittent open or open circuit condition has been detected on the fuel injector circuit, MAG side cylinder. It is possible that the injector or its interconnect harness have an intermittent open or an open circuit. To clear the fault code correct the injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds) then turn the key to the ON position. |

| P0217 | Engine Coolant Over Temperature Condition | The engine coolant temperature is too high for engine operation. Possible causes for this code are poor snow conditions, engine coolant level is low, or the water pump may not be circulating coolant properly. To clear the fault code, correct the engine coolant over temperature condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0219 | Engine Over-Speed Condition | The ECM has detected the engine RPM has exceeded the ECM’s engine RPM limit set point. It is possible the engine RPM is too high due to improper clutching. To clear the fault code, correct the engine over-speed condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0231 | Fuel Pump Relay Circuit Low/SG/Open | The ECM has detected a low voltage condition on the fuel pump relay output. It is possible the fuel pump relay has been removed or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the fuel pump relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0232 | Fuel Pump Relay Circuit High | The ECM has detected a high voltage condition on the fuel pump relay output. It is possible the fuel pump relay or its interconnect harness is shorted to battery power. To clear the fault code, correct the fuel pump relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0233 | Fuel Pump Relay Circuit Open | An open circuit condition has been detected on the coil side of the fuel pump relay. It is possible that the fuel pump relay in the PDM or its interconnect harness is open or not making a good connection. To clear the fault code, correct the fuel pump relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0237 | Turbocharger Boost Sensor Circuit Low | A low voltage condition has been detected on the Turbocharger Boost Sensor input. The Turbo Charger Boost sensor or its interconnect harness is open or shorted to ground. To clear the fault code, correct the Turbo Charger Boost Sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0238 | Turbocharger Boost Sensor Circuit High | A high voltage condition has been detected on the Turbocharger Boost Sensor input. The Turbo Charger Boost sensor or its interconnect harness is open or shorted to battery power. To clear the fault code, correct the Turbo Charger Boost Sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0243 | Turbocharger Wastegate Solenoid | The ECM has detected a lack of current when activating the Turbocharger Wastegate circuit. It is possible the Turbocharger Wastegate or its interconnect harness is open, shorted to ground, or shorted to battery power. To clear the fault code, correct the Turbocharger Wastegate Solenoid circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0261 | Cylinder 1 Injector Circuit Low | The ECM has detected a low voltage condition has been detected on the injector circuit output, for the PTO side cylinder. It is possible the injector or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0262 | Cylinder #1 Fuel Injector Circuit High | The ECM has detected a high voltage condition on the cylinder #1 fuel injector output. It is possible the cylinder #1 fuel injector or its interconnect harness is shorted to battery power. To clear the fault code, correct the cylinder #1 fuel injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0263 | Cylinder #1 Fuel Injector Circuit Balance/Open | The ECM has detected an intermittent voltage condition on the cylinder #1 fuel injector output. It is possible the cylinder #1 fuel injector or its interconnect harness is open. To clear the fault code, correct the cylinder #1 fuel injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0264 | Cylinder #2 Injector Circuit Low/SG | The ECM has detected a low voltage condition on the cylinder #2 fuel injector output. It is possible the cylinder #2 fuel injector or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the cylinder #2 fuel injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0266 | Cylinder #2 Fuel Injector Circuit Balance/Open | The ECM has detected an intermittent voltage condition on the cylinder #2 fuel injector output. It is possible the cylinder #2 fuel injector or its interconnect harness is open. To clear the fault code, correct the cylinder #2 fuel injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0267 | Cylinder 3 Injector Circuit Low | A low voltage condition has been detected on the injector circuit output, for the MAG side cylinder. It is possible the injector or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the injector circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0324 | Knock Control System Activated | Detonation has been detected by the knock sensor, ignition timing has been reduced but detonation still exists. If the system cannot eliminate the knock by reducing timing within the set parameters, it goes into a knock control system error in which case fuel is added and the code P0324 will flash on the gauge. Fuel is added to try and eliminate the knock, but power will be reduced and the operating RPM will be limited to 7700 RPM’s to try and protect the engine from damage. Poor fuel quality, elevated intake air and engine coolant temperatures, low fuel pressure, intake air leaks or any after-market components may cause this code, the knock sensor is working as designed. To clear the fault code, correct the condition and then restart the engine. |

| P0327 | Knock Sensor 1 Circuit Low | A low voltage condition has been detected on the knock sensor circuit input. It is possible the knock sensor or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the knock sensor circuit condition and then restart the engine. |

| P0328 | Knock Sensor 1 Circuit High | A high voltage condition has been detected on the knock sensor circuit input. It is possible the knock sensor or its interconnect harness is shorted to regulated voltage. To clear the fault code, correct the knock sensor circuit condition and then restart the engine. |

| P0336 | Crankshaft Angle Sensor Synchronization | The ECM was unable to synchronize the engine due to an intermittent signal from the crankshaft angle sensor. It is possible the crankshaft angle sensor or its interconnect harness are faulty causing the intermittent signal. This could also be caused by poor cranking speeds when trying to start the engine which may be caused my valves out of adjustment, weak battery, etc. To clear the fault code, correct the crankshaft angle sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0337 | Crankshaft Angle Sensor Circuit SG | The ECM has detected a low voltage condition on the crankshaft angle sensor circuit input. It is possible the crankshaft angle sensor or its interconnect harness are shorted to chassis ground. To clear the fault code, correct the crankshaft angle sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0339 | Crankshaft Angle Sensor Circuit Intermittent | The ECM has detected an intermittent voltage condition on the crankshaft angle sensor circuit input. It is possible the crankshaft angle sensor or its interconnect harness are faulty causing the intermittent voltage signal. To clear the fault code, correct the crankshaft angle sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0340 | Camshaft Angle Sensor Synchronization | The ECM was unable to synchronize the engine due to an intermittent signal from the camshaft angle sensor. It is possible the camshaft angle sensor or its interconnect harness are faulty causing the intermittent signal. This could also be caused by poor cranking speeds when trying to start the engine, which may be caused by valves out of adjustment, weak battery, etc. To clear the fault code, correct the camshaft angle sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0341 | Camshaft Angle Sensor Circuit SG | The ECM has detected a low voltage condition on the camshaft angle sensor circuit input. It is possible the camshaft angle sensor or its interconnect harness are shorted to chassis ground. To clear the fault code, correct the camshaft angle sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0342 | Camshaft Angle Sensor Circuit Intermittent | The ECM has detected an intermittent voltage condition on the camshaft angle sensor circuit input. It is possible the camshaft angle sensor or its interconnect harness are faulty causing the intermittent voltage signal. To clear the fault code, correct the camshaft angle sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0351 | Ignition Coil “A” Primary/Secondary Circuit | An open circuit condition has been detected on the MAG side cylinder ignition coil. It is possible the ignition coil or interconnect harness has an open circuit. To clear the fault code, correct the ignition coil circuit condition and then restart the engine. |

| P0352 | Ignition Coil “B” Primary/Secondary Circuit | An open circuit condition has been detected on the PTO side cylinder ignition coil. It is possible the ignition coil or interconnect harness has an open circuit. To clear the fault code, correct the ignition coil circuit condition and then restart the engine. |

| P0353 | Ignition Coil “C” Primary/Secondary Circuit | The ECM has detected a lack of current when activating the MAG ignition coil. It is possible the ignition coil or its interconnect harness is open, shorted to ground, or shorted to battery power. To clear the fault code, correct the ignition coil “C” primary control circuit high condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0480 | Cooling Fan Relay Circuit Open | An open circuit has been detected on the coil side of the cooling fan relay. It is possible that the cooling fan relay is open or not making a good connection. To clear the fault code, correct the cooling fan relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0481 | Fan-Secondary/Left Relay Control Circuit High | The ECM has detected a high voltage condition on the secondary fan relay output. It is possible the secondary fan relay or its interconnect harness are shorted to battery power. To clear the fault code, correct the secondary fan relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0482 | Fan-Secondary/Left Relay Control Circuit Low/SG/Open | The ECM has detected a low voltage condition on the secondary fan relay output. It is possible the secondary fan fuse is faulty, the relay has been removed, or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the secondary fan relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0483 | Fan-Secondary/Left Relay Control Circuit | The ECM has detected an intermittent voltage condition on the secondary fan relay output. It is possible the primary fan relay or its interconnect harness are faulty causing the intermittent voltage signal. To clear the fault code, correct the secondary fan relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0484 | Cooling Fan Relay Circuit High | A high voltage condition has been detected on the coil side of the cooling fan relay. It is possible that the cooling fan relay shorted to battery power. To clear the fault code, correct the cooling fan relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0485 | Cooling Fan Relay Circuit Low | A low voltage condition has been detected on the coil side of the cooling fan relay. It is possible that the cooling fan relay shorted to chassis ground. To clear the fault code, correct the cooling fan relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0500 | Vehicle Speed Sensor | The ECM has detected an intermittent voltage condition on the vehicle speed sensor input. It is possible the vehicle speed sensor or its interconnect harness is faulty causing the intermittent voltage signal. To clear the fault code, correct the vehicle speed circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0505 | Idle Control System F/B Malfunction | The ECM has detected the engine RPM at idle is outside the allowable range. Check the intake system for leaks which could cause the engine RPM to be outside the allowable idle RPM range. To clear the fault code, correct the idle control system F/B circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0508 | Idle Air Control System Circuit Low/SG | A low voltage condition has been detected on the ISC control circuit. It is possible the ISC or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the ISC circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0509 | Idle Air Control System Circuit High | A high voltage condition has been detected on the ISC control circuit. It is possible the ISC or its interconnect harness is open or shorted to battery power. To clear the fault code, correct the ISC circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0511 | Idle Air Control System Circuit | An open circuit condition has been detected on the ISC control circuit. It is possible the ISC or its interconnect harness is open. To clear the fault code, correct the ISC circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0522 | Engine Oil Pressure Sensor Circuit Low | A low voltage condition has been detected on the engine oil pressure sensor input circuit. It is possible the engine oil pressure sensor or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the engine oil pressure sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0523 | Engine Oil Pressure Sensor Circuit High | A high voltage condition has been detected on the engine oil pressure sensor input circuit. It is possible the engine oil pressure sensor or its interconnect harness is shorted to battery power. To clear the fault code, correct the engine oil pressure sensor circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0524 | Engine Oil Pressure Low | A low oil pressure condition has been detected. The engine oil pressure is lower than expected, check the oil level and for proper pressure. To clear the fault code, correct the Engine Oil Pressure Low condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0545 | Exhaust Gas Temperature Sensor Circuit Low | A low voltage condition has been detected on the exhaust gas temperature sensor circuit input. It is possible the exhaust gas temperature sensor or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the exhaust gas temperature sensor circuit condition and then restart the engine. |

| P0546 | Exhaust Gas Temperature Sensor Circuit High | A high voltage condition has been detected on the exhaust gas temperature sensor circuit input. It is possible the exhaust gas temperature sensor or its interconnect harness is shorted to regulated voltage. To clear the fault code, correct the exhaust gas temperature sensor circuit condition and then restart the engine. |

| P0562 | System Voltage Low | A low voltage condition has been detected on the system power circuit. It is possible the regulator/rectifier output or the battery charge condition is low. To clear the fault code, correct the battery charging circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0563 | System Voltage High | A high voltage condition has been detected on the system power circuit. It is possible the regulator/rectifier output is high or the battery cable connections may be loose. To clear the fault code, correct the battery charging circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0601 | ECM CAN Communication Shutdown | The ECM has detected an intermittent or unstable CAN communication condition. It is possible the CAN communication wires are faulty causing the ECM to temporarily shut down the CAN communication. To clear the fault code, correct the ECM CAN communication condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P062F | Internal Control Module EEPROM Error | The ECM has detected an error with the information stored in the EEPROM. Check wires and connectors for damage, corrosion, or potential shorts which could cause ECM damage. To clear the fault code, the ECM must be replaced. |

| P0615 | Starter Relay Circuit | The ECM has detected an intermittent voltage condition on the starter relay circuit. It is possible the starter switch/button, starter relay, gear switch or its interconnect harness are faulty causing the intermittent starter relay signal. To clear the fault code, correct the starter relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0616 | Starter Relay Circuit Low | The ECM has detected a low voltage condition on the starter relay circuit. It is possible the starter switch/button, starter relay or its interconnect harness are shorted to chassis ground. To clear the fault code, correct the starter relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0617 | Starter Relay Circuit High | The ECM has detected a high voltage condition on the starter relay circuit. It is possible the starter switch/button, starter relay or its interconnect harness are shorted to battery power. To clear the fault code, correct the starter relay circuit condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0630 | VIN Not Programmed or Incompatible | The ECM has detected a VIN compatibility condition. It is possible the LCD gauge or ECM on the vehicle is not correct, verify the part numbers of these parts for the vehicle being worked on. To clear the fault code, correct the VIN not programmed condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0642 | Sensor Power Circuit Low | The ECM has detected a low voltage condition on the sensor power circuit. It is possible one or more of the sensors is defective or shorted to chassis ground. To clear the fault code, correct the sensor power circuit low condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0643 | Sensor Power Circuit High | The ECM has detected a high voltage condition on the sensor power circuit. It is possible one or more of the sensors is defective or shorted to battery power. To clear the fault code, correct the sensor power circuit high condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0780 | Shift Error | A gear change was not detected when the command was given to change gears. It is possible the reverse actuator, forward relay, reverse relay or gear position switch may be faulty or not connected. To clear the fault code, verify that the relays are activating the reverse actuator and gear position switch when an attempt is made, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P0919 | Shift Switch Stuck | The ECM has received a request to shift for more than 30 seconds. It is possible the shift switch on the handlebar is stuck or the switch or interconnect harness is shorted to ground causing the constant signal sent to the ECM. To clear the fault code, correct the shift switch stuck condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1000 | Oil Pump Flow Not Programmed | The ECM does not have oil pump flow data stored in its memory. It is possible that the ECM has never been initialized with oil pump flow data. Using the oil pump replacement procedure, enter the data as it appears on the oil pump ID tag. To clear the fault code, correct the oil pump flow not programmed condition, then restart the engine. |

| P1001 | Injector 1 Offset Not Programmed | The ECM does not have injector flow data for the MAG side cylinder stored in its memory. It is possible that the ECM has never been initialized with injector flow data for the MAG side cylinder. Using the injector replacement procedure, enter the data as it appears on the injector ID tag. To clear the fault code, correct the injector flow not programmed condition, then restart the engine. |

| P1002 | Injector 2 Offset Not Programmed | The ECM does not have injector flow data for the PTO side cylinder stored in its memory. It is possible that the ECM has never been initialized with injector flow data for the PTO side cylinder. Using the injector replacement procedure, enter the data as it appears on the injector ID tag. To clear the fault code, correct the injector flow not programmed condition, then restart the engine. |

| P1003 | Oil Pump Outlier | The oil pump drive voltage is detected as out of range. It is possible the oil pump or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the oil pump outlier condition, then restart the engine. |

| P1004 | ISC Outlier | The ISC drive voltage is detected as out of range. It is possible the ISC or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the ISC outlier condition, then restart the engine. |

| P1005 | Regulator Voltage Circuit Low | A low voltage condition has been detected on the voltage regulator output. It is possible the voltage regulator is not producing enough voltage due to a faulty regulator or stator. It could also be caused by an excessive current draw causing the low voltage condition. To clear the fault code, correct the regulator voltage circuit condition, then restart the engine. |

| P1006 | Regulator Voltage Circuit High | A high voltage condition has been detected on the voltage regulator output. It is possible the voltage regulator is producing too high of a voltage due to a faulty regulator. To clear the fault code, correct the regulator voltage circuit condition, then restart the engine. |

| P1007 | Fuel Pump Circuit Low | A low voltage condition has been detected on the fuel pump circuit. It is possible the fuel pump or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the fuel pump circuit condition, then restart the engine. |

| P1008 | Fuel Pump Circuit High | A high voltage condition has been detected on the fuel pump circuit. It is possible the fuel pump or its interconnect harness is shorted to regulated voltage. To clear the fault code, correct the fuel pump circuit condition, then restart the engine. |

| P1009 | Speed Sensor Malfunction | The ECM has detected an error with the speed sensor circuit due to inputs from the speed sensor, engine RPM, and TPS. It is possible the speed sensor or its interconnect harness is open or shorted to a steady voltage. To clear the fault code, correct the speed sensor malfunction condition, then restart the engine. |

| P100A | Run-A-Way Prevention System Activated | The Run-A-Way Prevention System has been activated and the engine shut down. The TPS voltage has exceeded its threshold with no input from the RPS switch. The RPS switch or interconnect harness may be open. To clear the fault code, correct the Run-A-Way Prevention System condition, and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1106 | MAP Sensor Hose Disconnect | The ECM has detected the hose from the MAP sensor is disconnected from the sensor or the intake manifold. Check the hose for proper connections and ensure there are no leaks which could cause erratic readings. To clear the fault code, correct the MAP Sensor Hose Disconnect condition, and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1236 | Turbocharger Boost Sensor Hose Disconnect | The ECM has detected the hose from the Turbocharger Boost sensor is disconnected from the sensor or the intake system. Check the hose for proper connections and ensure there are no leaks which could cause erratic readings. To clear the fault code, correct the Turbocharger Boost Sensor Hose Disconnect condition, and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1261 | Injector Circuit/Open – Cylinder 1b | A low current draw condition has been detected on the MAG side cylinder sub-injector output. It is possible the injector or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the injector circuit/open condition, then restart the engine. |

| P1264 | Injector Circuit/Open – Cylinder 2b | A low current draw condition has been detected on the PTO side cylinder sub-injector output. It is possible the injector or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the injector circuit/open condition, then restart the engine. |

| P1315 | Crankshaft Position Out of Sync | The ECM was unable to determine the crankshaft position from the signal given by the crankshaft position sensor. It is possible that the crankshaft position sensor is faulty or the CPS may have debris on it causing a poor signal. Before replacing the CPS, verify that the battery is in good health, connections from the battery to the starter are tight, and that the engine is turning over properly. To clear the fault code, correct the crankshaft position out of sync condition, and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1324 | Knock Control System Activated | Detonation has been detected by the knock sensor, ignition timing has been reduced but detonation still exists. If the system cannot eliminate the knock by reducing timing within the set parameters, it goes into a knock control system error in which case fuel is added and the code P0324 will flash on the gauge. Fuel is added to try and eliminate the knock, but power will be reduced and the operating RPM will be limited to 7700 RPM to try and protect the engine from damage. Poor fuel quality, elevated intake air and engine coolant temperatures, low fuel pressure, intake air leaks, or any after-market components may cause this code. The knock sensor is working as designed. To clear the fault code, correct the injector circuit condition, and then restart the engine. |

| P1329 | Knock Sensor Loose Detection | The ECM has detected the knock sensor may not be mounted tightly by interpreting the signal sent from the knock sensor. The knock sensor may not be properly torqued causing this fault code. To clear the fault code, correct the knock sensor loose condition, then restart the engine. |

| P1335 | Crank not detected while starting | The ECM has detected the Start Switch has been engaged with no RPM signal detected. The Crankshaft Position Sensor or its interconnect harness may be open or shorted to ground. If the engine does not turn over, the starter solenoid circuit may be malfunctioning. To clear the fault code, correct the crank not detected while starting condition, and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1338 | Crankshaft Spike Detected | The ECM has detected an abnormal spike in the signal from the CPS. It is possible that the signal from the CPS to the ECM is intermittent or the signal is out of the defined parameters due to inconsistent cranking speed, improper combustion, or a faulty CPS sensor. To clear the fault code, correct the crankshaft spike detected condition, and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1339 | Crankshaft Tooth Not Detected | The ECM has detected an incorrect number of teeth in the signal sent from the CPS. It is possible that the air gap from the CPS to the timing gear on the output shaft assembly is out of specification, the CPS is reading an incorrect number of teeth due to debris on the CPS or CPS is faulty. To clear the fault code, correct the crankshaft tooth not detected condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1520 | Engine Oil Pressure Switch Circuit | The ECM has detected an error on the Oil Pressure switch circuit. The Engine Oil Pressure Switch circuit or its interconnect harness may be open. To clear the fault code, correct the Engine Oil Pressure Switch Circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1522 | Engine Oil Pressure Sensor Circuit Low | A low voltage condition has been detected on the Oil Pressure Sensor input. The Engine Oil Pressure sensor or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the Engine Oil Pressure Sensor Circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1523 | Engine Oil Pressure Sensor Circuit High | A high voltage condition has been detected on the Oil Pressure Sensor input. The Engine Oil Pressure sensor or its interconnect harness is open or shorted to battery power. To clear the fault code, correct the Engine Oil Pressure Sensor Circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1636 | Crank Angle Sensor Circuit | The ECM has detected a problem with the crank angle sensor circuit due to the signal sent from the crank angle sensor. It is possible the crank angle sensor or its interconnect harness is open or shorted to a constant voltage not allowing the ECM to properly read the 11-tooth signal on the magneto. To clear the fault code, correct the crank angle sensor circuit condition, then restart the engine. |

| P1639 | Exhaust Valve Position Sensor Circuit Low | A low voltage condition has been detected on the exhaust valve position sensor circuit input. It is possible the exhaust valve position sensor or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the exhaust valve position sensor circuit condition, then restart the engine. |

| P1640 | Exhaust Valve Position Sensor Circuit High | A high voltage condition has been detected on the exhaust valve position sensor circuit input. It is possible the exhaust valve position sensor or its interconnect harness is shorted to regulated voltage. To clear the fault code, correct the exhaust valve position sensor circuit condition, then restart the engine. |

| P1645 | Exhaust Valve System Malfunction | The exhaust valve system is not operating as expected. It is possible the exhaust valve is out of the specified range or it is physically stuck and unable to move as requested by the ECM. Proper exhaust valve cable length should always be checked when there is an error within the exhaust valve system. When checking the free length, also verify that the valves move freely and return to the closed position when released. To clear the fault code, correct the exhaust valve system malfunction condition, then restart the engine. |

| P1646 | Exhaust Valve Actuator Self-Cleaning Open Error | An open circuit condition was detected while the ECM was self-calibrating the exhaust valve range by attempting a full sweep of the actuator. It is possible the exhaust valve actuator or its interconnect harness has an open circuit. To clear the fault code, correct the exhaust valve actuator self-cleaning open error condition, then restart the engine. |

| P1647 | Exhaust Valve Actuator Short Error | A short circuit condition was detected while the ECM was self-calibrating the exhaust valve range by attempting a full sweep of the actuator. It is possible the exhaust valve actuator or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the exhaust valve actuator short error condition, then restart the engine. |

| P1685 | Main Relay Open Circuit | An open circuit has been detected on the coil side of the ISC relay. It is possible that the ISC relay in the PDM is not making connection or the wiring to the ISC relay is open due to a broken wire. To clear the fault code, correct the main relay open circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1686 | Main Relay Circuit Low | A low voltage condition has been detected on the coil side of the ISC relay. It is possible that the ISC relay in the PDM or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the main relay circuit low condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1687 | Main Relay Circuit High | A high voltage condition has been detected on the coil side of the ISC relay. It is possible that the ISC relay or its interconnect harness is shorted to battery power. To clear the fault code, correct the main relay circuit high condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1688 | Reverse Relay Open Circuit | An open circuit has been detected on the coil side of the reverse relay. It is possible that the reverse relay in the PDM is not making connection or the wiring to the reverse relay is open due to a broken wire. To clear the fault code, correct the reverse relay open circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1689 | Reverse Relay Circuit Low | A low voltage condition has been detected on the coil side of the reverse relay. It is possible that the reverse relay in the PDM or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the reverse relay circuit low condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1690 | Reverse Relay Circuit High | A high voltage condition has been detected on the coil side of the reverse relay. It is possible that the reverse relay in the PDM or its interconnect harness is shorted to battery power. To clear the fault code, correct the reverse relay circuit high condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1691 | Forward Relay Open Circuit | An open circuit has been detected on the coil side of the forward relay. It is possible that the forward relay in the PDM is not making connection or the wiring to the forward relay is open due to a broken wire. To clear the fault code, correct the forward relay open circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1692 | Forward Relay Circuit Low | A low voltage condition has been detected on the coil side of the forward relay. It is possible that the forward relay in the PDM or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the forward relay circuit low condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1693 | Forward Relay Circuit High | A high voltage condition has been detected on the coil side of the forward relay. It is possible that the forward relay in the PDM or its interconnect harness is shorted to battery power. To clear the fault code, correct the forward relay circuit high condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1694 | Headlight Relay Open Circuit | An open circuit has been detected on the coil side of the headlight relay. It is possible that the headlight relay in the PDM is not making connection or the wiring to the headlight relay is open due to a broken wire. To clear the fault code, correct the headlight relay open circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1695 | Headlight Relay Circuit Low | A low voltage condition has been detected on the coil side of the headlight relay. It is possible that the headlight relay in the PDM or its interconnect harness is shorted to chassis ground. To clear the fault code, correct the headlight relay circuit low condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1696 | Headlight Relay Circuit High | A high voltage condition has been detected on the coil side of the headlight relay. It is possible that the headlight relay in the PDM or its interconnect harness is shorted to battery power. To clear the fault code, correct the headlight relay circuit high condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1704 | Fuel Pump Relay Circuit Low | A low voltage condition has been detected on the coil side of the fuel pump relay. It is possible that the fuel pump relay in the PDM or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the fuel pump relay circuit low condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1705 | Fuel Pump Relay Circuit High | A high voltage condition has been detected on the coil side of the fuel pump relay. It is possible that the fuel pump relay in the PDM or its interconnect harness is shorted to battery power. To clear the fault code, correct the fuel pump relay circuit high condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P1755 | Engine RPM Sensor Circuit Malfunction | The ECM has detected a problem with the engine RPM sensor circuit due to the signal sent from the engine RPM sensor. It is possible the engine RPM sensor or its interconnect harness is open or shorted to a constant voltage not allowing the ECM to properly read the 2-tooth signal on the magneto. To clear the fault code, correct the engine RPM sensor circuit condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position or restart the engine. |

| P2228 | Barometric Pressure Sensor “A” Circuit Low | A low voltage condition has been detected on the barometric pressure sensor input. It is possible the barometric pressure sensor or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the barometric pressure sensor circuit condition, then restart the engine. |

| P2229 | Barometric Pressure Sensor “A” Circuit High | A high voltage condition has been detected on the barometric pressure sensor input. It is possible the barometric pressure sensor or its interconnect harness is shorted to battery power/regulated voltage. To clear the fault code, correct the barometric pressure sensor circuit condition, then restart the engine. |

| P2282 | Air Leak Between Throttle Body and Intake Valves | The ECM has detected that the calculated Mass Air Flow value is implausible. It is possible that the throttle body has come loose causing an air leak between the throttle body and the intake valves. To clear the fault code, correct the air leak between the throttle body and intake valve condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P2300 | Ignition Coil “A” Primary Control Circuit Low | A low voltage condition has been detected on the PTO side cylinder ignition coil. It is possible the ignition coil or its interconnect harness is open or shorted to chassis ground. To clear the fault code, correct the ignition coil “A” primary control circuit low condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| P2301 | Ignition Coil “A” Primary Control Circuit High | A high voltage condition has been detected on the MAG side cylinder ignition coil. It is possible the ignition coil or its interconnect harness is shorted to battery power. To clear the fault code, correct the ignition coil “A” primary control circuit high condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1301 | Over Current | The EPS has detected that the internal current is above the allowed set point. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the over current condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1302 | Excessive Current Error | The EPS has detected that there is an internal current measurement error. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the excessive current condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1303 | Torque Sensor Range Fault | The EPS has detected that there is an internal torque sensor range condition. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the torque sensor range condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1304 | Torque Sensor Linearity Fault | The EPS has detected that there is an internal torque sensor linearity condition. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the torque sensor linearity condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1305 | Rotor Position Encoder | The EPS has detected that there is an internal rotor position encoder condition. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the rotor position encoder condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1306 | System Voltage Low | The EPS has detected a low battery voltage condition due to the voltage being supplied to the EPS being below 11 DC volts. It is possible that this has been caused by a faulty wire harness to the EPS, faulty voltage regulator, inadequate battery voltage, or loose battery cable connections. The fault code will be cleared when the battery voltage returns to its specified range. |

| C1307 | System Voltage High | The EPS has detected a high battery voltage condition due to the voltage being supplied to the EPS being above 16 DC volts. It is possible that this has been caused by a faulty wire harness to the EPS, faulty voltage regulator, or loose battery cable connections. The fault code will be cleared when the battery voltage returns to its specified range. |

| C1308 | Temperature Above 110°C | The EPS has detected its internal temperature is above 110°C. It is possible that this has been caused by dirt and contaminants preventing the cooling fins from properly cooling the EPS unit. It is recommended to clean the exterior of the EPS unit to allow for proper airflow to cool the EPS unit. The fault code will be cleared when the internal temperature of the EPS drops below 105°C. |

| C1309 | Temperature Above 120°C | The EPS has detected its internal temperature is above 120°C. It is possible that this has been caused by dirt and contaminants preventing the cooling fins from properly cooling the EPS unit. It is recommended to clean the exterior of the EPS unit to allow for proper airflow to cool the EPS unit. The fault code will be cleared when the internal temperature of the EPS drops below 115°C. |

| C1310 | Vehicle Speed High | The EPS has detected the vehicle speed signal received exceeds the maximum speed specification. It is possible that this has been caused by a faulty speed sensor or intermittent signals due to faulty speed sensor wires or main harness wires. The fault code will be cleared when the vehicle speed signal drops below its maximum speed specification. |

| C1311 | Vehicle Speed Low | The EPS has detected the vehicle speed signal received is zero or missing. It is possible that this has been caused by a faulty speed sensor or intermittent signals due to faulty speed sensor wires or main harness wires. The fault code will be cleared when the vehicle speed signal is received by the EPS unit. |

| C1312 | Vehicle Speed Faulty | The EPS has detected the vehicle speed CAN signal received is incorrect or missing. It is possible that this has been caused by a faulty speed sensor or intermittent signals due to faulty speed sensor wires or main harness wires. The fault code will be cleared when the correct vehicle speed signal is received by the EPS unit. |

| C1313 | Engine Speed High | The EPS has detected the RPM signal received exceeds the maximum RPM specification. The fault code will be cleared when the RPM signal drops below its maximum specification. |

| C1314 | Engine Speed Low | The EPS has detected the RPM signal received suddenly dropped below 500 RPM. The fault code will be cleared when the RPM signal received by the EPS unit goes above 500 RPM. |

| C1315 | Engine Speed Faulty | The EPS has detected the RPM CAN signal received is incorrect or missing. It is possible that this has been caused by faulty main harness wires or a faulty ECM. The fault code will be cleared when the correct vehicle speed signal is received by the EPS unit. |

| C1316 | EEPROM Error | The EPS has detected an error in its internal memory. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the EEPROM error condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1317 | CAN Bus Error | The EPS has detected a loss of CAN communication between the ECM and the EPS. It is possible that this has been caused by faulty CAN wires or an improper connection at the ECM. To clear the fault code, correct the CAN bus error condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1318 | Internal CRC Error | The EPS has detected an internal CRC calculation condition. It is possible that this has been caused by a failed reflash due to loss of battery power during reflash programming. To clear the fault code, the EPS must be properly programmed. |

| C1319 | Boot Counter Exceeded | The EPS has detected an internal application code condition. It is possible that this has been caused due to an unsuccessful application launch due to intermittent power supplied to the EPS. To clear the fault code, correct the boot counter exceeded condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1320 | Incorrect Vehicle Speed to RPM Ratio | The EPS has detected the vehicle speed is greater than 10 MPH and the engine RPM signal is less than 500 RPM. To clear the fault code, correct the incorrect vehicle speed to RPM ratio condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1321 | Vehicle Speed Erratic | The EPS has detected that the vehicle speed signal is changing at unrealistic rates. It is possible that this has been caused due to a faulty speed sensor, dirty speed sensor or trigger wheel, or an intermittent connection in the main harness. To clear the fault code, correct the vehicle speed erratic condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1322 | Engine RPM Lost | The EPS has detected that engine RPM signal is above 500 RPM and then drops to zero or goes missing causing an erratic signal. The fault code will be cleared when the correct engine RPM signal is received by the EPS unit. |

| C1323 | “EPS OFF” Gauge Display | The EPS has detected there is no RPM signal but battery power has been applied for 5 minutes. It is possible that this has been caused due to a customer leaving the key in the ON position. The fault code will be cleared when the correct engine RPM signal is received by the EPS unit or by turning the key to the OFF position (for a minimum of 10 seconds), then turning the key to the ON position. |

| C1324 | Loss of CAN Communication with EPS Unit | The gauge has detected there is no CAN communication with the EPS unit. It is possible that this has been caused due to faulty CAN wire in the main harness or a faulty connection at the EPS. The fault code will be cleared when the correct CAN communication signal is received by the gauge. |

| C1325 | Dual Loss | The EPS unit has detected there is no vehicle speed or engine RPM signal being sent to the EPS unit. It is possible that this has been caused due to the handlebar switch in the OFF position, the engine has stalled with the key in the ON position, a faulty wire harness or the loss of the CAN data signal. The fault code will be cleared when either the vehicle speed or engine RPM signal is received by the EPS unit. |

| C1326 | Rotor Position Encoder | The EPS has detected an internal rotor position encoder variance. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the rotor position encoder condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1327 | Voltage Converter Error (Low) | The EPS has detected a low voltage condition on the internal voltage converter. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the voltage converter error condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1328 | Voltage Converter Error (High) | The EPS has detected a high voltage condition on the internal voltage converter. It is possible that this has been caused by an internal EPS condition. To clear the fault code, correct the voltage converter error condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1329 | Internal Data Error | The EPS has detected an internal preloaded data condition. It is possible that this has been caused by an internal EPS condition. To clear the fault code, the EPS unit will have to be reprogrammed. |

| C1400 | Fuel Sender Open | The gauge has detected an open circuit condition in the fuel sender circuit. It is possible that this has been caused due to an open circuit or disconnect in the fuel sender or its interconnect harness. To clear the fault code, correct the fuel sender condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1401 | Fuel Sender High | The gauge has detected a high voltage condition in the fuel sender circuit. It is possible that this has been caused due to the fuel sender or its interconnect harness shorted to battery power. To clear the fault code, correct the fuel sender condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1402 | Fuel Sender Low | The gauge has detected a low voltage condition in the fuel sender circuit. It is possible that this has been caused due to the fuel sender or its interconnect harness shorted to chassis ground. To clear the fault code, correct the fuel sender condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1403 | Input #1 Open | The gauge has detected an open circuit condition in the input #1 circuit. It is possible that this has been caused due to an open circuit or disconnect in the input #1 or its interconnect harness. To clear the fault code, correct the input #1 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1404 | Input #1 High | The gauge has detected a high voltage condition in the Input #1 circuit. It is possible that this has been caused due to the Input #1 or its interconnect harness shorted to battery power. To clear the fault code, correct the Input #1 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1405 | Input #1 Low | The gauge has detected a low voltage condition in the Input #1 circuit. It is possible that this has been caused due to the Input #1 or its interconnect harness shorted to chassis ground. To clear the fault code, correct the Input #1 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1406 | Input #2 Open | The gauge has detected an open circuit condition in the input #2 circuit. It is possible that this has been caused due to an open circuit or disconnect in the input #2 or its interconnect harness. To clear the fault code, correct the input #2 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1407 | Input #2 High | The gauge has detected a high voltage condition in the Input #2 circuit. It is possible that this has been caused due to the Input #2 or its interconnect harness shorted to battery power. To clear the fault code, correct the Input #2 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1408 | Input #2 Low | The gauge has detected a low voltage condition in the Input #2 circuit. It is possible that this has been caused due to the Input #2 or its interconnect harness shorted to chassis ground. To clear the fault code, correct the Input #2 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1409 | Input #3 Open | The gauge has detected an open circuit condition in the input #3 circuit. It is possible that this has been caused due to an open circuit or disconnect in the input #3 or its interconnect harness. To clear the fault code, correct the input #3 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1410 | Input #3 High | The gauge has detected a high voltage condition in the Input #3 circuit. It is possible that this has been caused due to the Input #3 or its interconnect harness shorted to battery power. To clear the fault code, correct the Input #3 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1411 | Input #3 Low | The gauge has detected a low voltage condition in the Input #3 circuit. It is possible that this has been caused due to the Input #3 or its interconnect harness shorted to chassis ground. To clear the fault code, correct the Input #3 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1412 | Input #4 Open | The gauge has detected an open circuit condition in the input #4 circuit. It is possible that this has been caused due to an open circuit or disconnect in the input #4 or its interconnect harness. To clear the fault code, correct the input #4 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1413 | Input #4 High | The gauge has detected a high voltage condition in the Input #4 circuit. It is possible that this has been caused due to the Input #4 or its interconnect harness shorted to battery power. To clear the fault code, correct the Input #4 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1414 | Input #4 Low | The gauge has detected a low voltage condition in the Input #4 circuit. It is possible that this has been caused due to the Input #4 or its interconnect harness shorted to chassis ground. To clear the fault code, correct the Input #4 condition and then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1415 | App Reflash Error | The gauge has detected an unstable application code during or after a reflash. This could be caused by intermittent power or unstable communication during the reflash, preventing a successful app reflash. To clear the fault code, correct the gauge power or communication condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. The gauge may need to be reflashed at this time. |

| C1416 | Cal Reflash Error | The gauge has detected an unstable calibration code during or after a reflash. This could be caused by intermittent power or unstable communication during the reflash, preventing a successful app reflash. To clear the fault code, correct the gauge power or communication condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. The gauge may need to be reflashed at this time. |

| C1417 | Internal Hardware Fault | The gauge has detected an internal hardware condition, possibly caused by one or more internal components or systems not responding due to a poor connection between the gauge and the main harness. To clear the fault code, correct the internal hardware fault condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1418 | Memory Power Fault | The gauge has detected a low voltage condition on the clock memory circuit. This could be caused by a faulty ACC, MEM, or memory fuse in the PDM. To clear the fault code, correct the memory power fault condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1419 | Output #1 Open | The gauge has detected an open circuit condition in the output #1 circuit, possibly due to an open circuit or disconnect in the output #1 or its interconnect harness. To clear the fault code, correct the output #1 condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1420 | Output #1 High | The gauge has detected a high voltage condition in the output #1 circuit, possibly due to the output #1 or its interconnect harness shorted to battery power. To clear the fault code, correct the output #1 condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1421 | Output #1 Low | The gauge has detected a low voltage condition in the output #1 circuit, possibly due to the output #1 or its interconnect harness shorted to chassis ground. To clear the fault code, correct the output #1 condition, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1422 | Incorrect App Code | The gauge has detected non-production application code in the internal app memory space. To clear the fault code, reflash the gauge with the appropriate software, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |

| C1423 | Incorrect Cal Code | The gauge has detected non-production calibration code in the internal cal memory space. To clear the fault code, reflash the gauge with the appropriate software, then turn the key to the OFF position (for a minimum of 10 seconds), then turn the key to the ON position. |