P0009 Code Explained: Engine Position System Performance – Bank 2 – Causes & Fixes

When you purchase through links on our site, we may earn an affiliate commission. See our affiliate disclaimer for more information.

What does the P0009 Engine Position System Performance – Bank 2 mean?

The P0009 trouble code indicates a problem with engine timing. Specifically, it means the Engine Control Module (ECM) has detected a misalignment between the crankshaft position and the camshaft position on Bank 2.

Modern engines rely on precise synchronization between the crankshaft and camshaft(s) to control valve timing accurately. When this relationship is outside the allowable range, the ECM sets the P0009 code to indicate an engine position system performance issue.

What Does Bank 2 Mean?

On engines with more than one cylinder bank, such as V6 or V8 engines, the engine is divided into Bank 1 and Bank 2.

- Bank 1 is the side of the engine that contains cylinder number one.

- Bank 2 is the opposite side.

The P0009 code applies only to Bank 2.

To learn how to diagnose car sensor–related issues and understand OBD-II codes, read our complete guide.

STOP GUESSING. START DIAGNOSING. SAVE HUNDREDS ON REPAIRS.

Tired of expensive repair bills and mechanics who “parts-cannon” your car without finding the real issue? The “Check Engine” light shouldn’t be a mystery. This guide puts professional-level diagnostics in your hands.

When Does the P0009 Code Trigger?

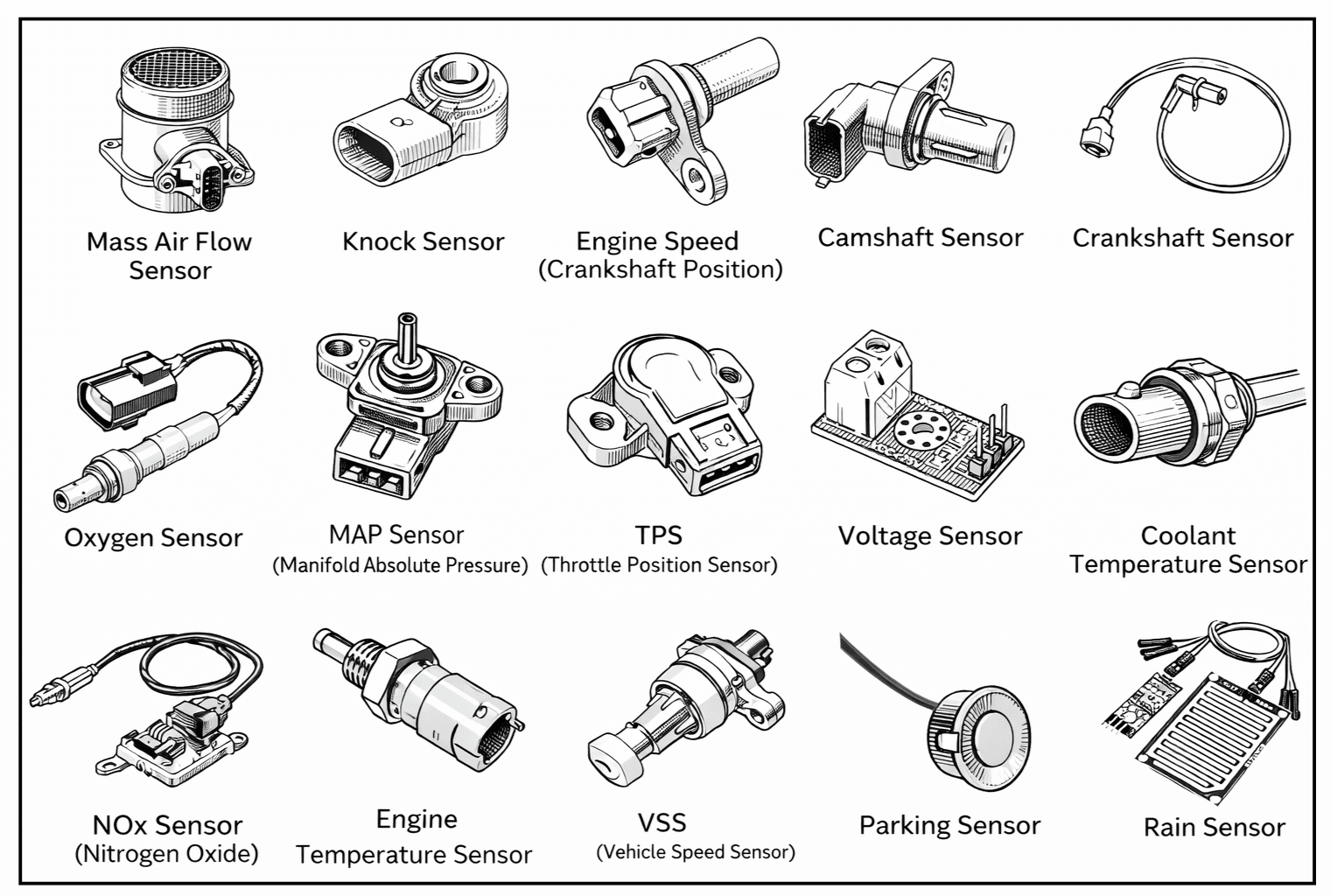

The engine uses two critical sensors to monitor timing:

The crankshaft position sensor tracks the exact position and rotational speed of the crankshaft, while the camshaft position sensor monitors the position of the camshaft(s). Both signals are continuously sent to the ECM.

The ECM constantly compares these signals to ensure the camshaft timing matches the crankshaft position as expected. When the ECM detects that the Bank 2 camshaft position is not aligned correctly with the crankshaft, and the deviation exceeds allowable limits, it triggers the P0009 diagnostic trouble code.

Read more about:

Car Sensors Explained: What They Do and How to Diagnose Them

With the increasing use of electronic systems in modern vehicles,…

Why Accurate Engine Timing Matters

Incorrect camshaft-to-crankshaft alignment can lead to:

- Poor engine performance

- Rough idle or misfires

- Reduced fuel efficiency

- Hard starting

- Potential internal engine damage if left unaddressed

Because timing-related faults can worsen over time, the P0009 code should be diagnosed and repaired promptly.

How To Fix P0009?

Troubleshooting P0009 involves several steps, and we’ll discuss each one in detail. Let’s get started!

Before diving into specific repairs, perform an OBD-II scanner reset to clear the codes. Sometimes, these codes pop up due to recent maintenance work and can resolve themselves after a reset.

To learn how to diagnose car sensor–related issues and understand OBD-II codes, read our complete guide.

STOP GUESSING. START DIAGNOSING. SAVE HUNDREDS ON REPAIRS.

Tired of expensive repair bills and mechanics who “parts-cannon” your car without finding the real issue? The “Check Engine” light shouldn’t be a mystery. This guide puts professional-level diagnostics in your hands.

To reset the error codes, use an OBD-II scanner. Simply connect the scanner to your vehicle, follow the instructions to clear the trouble codes, and see if the P0009 code reappears.

If the code comes back, it means there’s a persistent issue that needs further troubleshooting.

⚠️ Safety Considerations Before Fixing P0009

Before starting any diagnostics or repair work, keep these safety points in mind:

- Allow the engine to cool completely before working near timing components

- Disconnect the negative battery terminal to prevent electrical shorts

- Wear safety gloves and eye protection

- Do not rotate the engine manually unless timing marks are properly aligned

- If timing chain inspection is required, follow manufacturer service procedures carefully

Step-by-Step Guide to Fix OBD2 Code P0009

Step 1: Verify the Fault Code

Begin the diagnosis by verifying that P0009 – Engine Position System Performance (Bank 2) is actually present. Connect an OBD-II scan tool to the vehicle’s diagnostic port and read all stored and pending trouble codes. It is important not to focus on P0009 alone. Check for related correlation and timing codes such as P0008, P0016, or P0017, as these often appear together and indicate camshaft-to-crankshaft timing issues affecting one or both banks.

If multiple timing-related codes are stored, this usually points toward a mechanical timing problem, VVT system fault, or oil-related issue rather than a simple sensor failure. Record all codes and freeze-frame data before clearing anything, as this information helps guide further diagnosis.

Tools required:

OBD-II scan tool (basic or advanced)

Estimated time:

5–10 minutes

Estimated cost:

$0 if you already own a scan tool, or $20–$100 depending on scanner type (many parts stores scan for free)

- CEL Doctor: The ANCEL AD310 is one of the best-selling OBD II scanners on the market and is recommended by Scotty Kilmer…

- Sturdy and Compact: Equipped with a 2.5 foot cable made of very thick, flexible insulation. It is important to have a st…

- Accurate Fast and Easy to Use: The AD310 scanner can help you or your mechanic understand if your car is in good conditi…

Step 2: Check Engine Oil Level and Condition

The next step is to inspect the engine oil level and oil condition. Variable Valve Timing (VVT) systems rely heavily on clean oil and proper oil pressure to operate correctly. If the oil level is low, the oil is dirty or sludged, or the incorrect viscosity is being used, the VVT actuators may not respond as commanded. This can cause camshaft timing to drift out of specification and trigger engine position system performance codes such as P0008 or P0009.

Check the oil level using the dipstick and verify that it is within the manufacturer’s recommended range. Examine the oil condition as well. Oil that is excessively dark, thick, or contaminated indicates overdue oil changes or internal sludge buildup, both of which can interfere with VVT operation.

If the oil level is low, top it up using the correct oil grade. If the oil is dirty or the wrong viscosity is present, perform a full oil and filter change before continuing diagnosis. In many cases, correcting oil-related issues alone can resolve timing performance codes.

Tools required:

Engine oil dipstick, clean rag, correct engine oil (if topping up)

Estimated time:

5–15 minutes (oil change may take longer)

Estimated cost:

$0–$20 for oil top-up, or $40–$100 for an oil and filter change (depending on vehicle and oil type)

- Mobil 1 Advanced Fuel Economy full-synthetic motor oil 0W-20 is low-viscosity to help improve fuel economy.*

- Utilizes Mobil 1’s signature Triple Action Formula to deliver outstanding engine performance, protection, and cleanlines…

- Helps protect critical engine parts for up to 10,000 miles between oil changesm,** controlling oxidation to prevent oil …

Step 3: Inspect Camshaft Position Sensor Wiring (Bank 2)

Inspect the camshaft position sensor wiring and connector for Bank 2. Begin with a careful visual inspection of the wiring harness near the sensor, paying close attention to areas exposed to heat, vibration, or oil contamination. Look for damaged or cracked insulation, pinched wires, corrosion inside the connector, or terminals that appear loose or pushed back.

A poor electrical connection can cause intermittent or weak camshaft position signals, which may lead the ECM to misinterpret camshaft timing and trigger correlation or engine position system performance codes such as P0009. If any wiring damage or connector issues are found, repair them before continuing with further diagnosis.

Tools required:

Flashlight, basic hand tools (for connector access)

Estimated time:

10–20 minutes

Estimated cost:

$0–$30 (wiring repair or connector cleaning, if needed)

- Comprehensive Tool Set: The Cartman 148 Piece Tool Kit includes all the crucial tools needed for everyday home repairs a…

- Sturdy and Corrosion-Resistant: All tools in the kit are heat-treated, ensuring that they resist corrosion and remain st…

- Convenient Storage: The kit comes in a sturdy and handy blow-molded case, which securely houses each tool in its respect…

Step 4: Test the Camshaft Position Sensor

After confirming that the wiring and connector are in good condition, test the camshaft position sensor for Bank 2. Using a digital multimeter (DMM), verify that the sensor is receiving the correct reference voltage and ground from the ECM. Then check the sensor signal to ensure it changes consistently and smoothly according to manufacturer specifications.

An unstable, missing, or incorrect signal can cause the ECM to misinterpret camshaft position, leading to engine timing correlation errors such as P0009. If the measured voltage or signal behavior does not match the specified values, the sensor may be faulty and require replacement.

Tools required:

Digital multimeter (DMM), vehicle wiring diagram or service manual

Estimated time:

25–60 minutes

Estimated cost:

$0 if testing only, or $30–$150 if sensor replacement is required (varies by vehicle)

- Versatile Settings – The AstroAI Digital Multimeter accurately measures AC/DC Voltage, AC/DC Current, Resistance, Contin…

- Non-Contact Safety – This DMM is designed with safety in mind. The NCV Function minimizes exposure to live wires; the pr…

- Practical Features – When using a Multimeter, the small details like Data Hold, a Large Backlight LCD Screen, Kickstand,…

Step 5: Inspect the Timing Chain and Related Components

If all electrical components and sensors test correctly, the next step is to inspect the timing chain and related mechanical components. This requires removing the necessary engine covers to gain access to the timing assembly. Carefully examine the timing chain for signs of excessive stretch, skipped teeth, or misalignment. The timing chain guides and tensioners should also be inspected for wear, cracking, breakage, or loss of tension.

A worn or stretched timing chain, damaged guides, or a failing tensioner can allow the camshaft timing to drift out of specification, triggering engine position system performance codes such as P0008 or P0009. If mechanical timing issues are confirmed, replacing the timing chain along with the guides and tensioners is required to restore proper engine timing and prevent further engine damage.

Tools required:

Basic hand tools, torque wrench, timing tools (engine-specific), service manual

Estimated time:

3–8 hours (varies by engine design)

Estimated cost:

$800–$3,500 (parts and labor, depending on vehicle and engine configuration)

- 【Part Number】14510-R40-A01, 13620-RAA-A02, 14210-PNA-000, 14530-PPA-003, 14530-RAA-A01, 14530-RZA-A01, 14540-RWC-A02, 14…

- 【Compatible With】For Honda Acura ILX Accord Civic Crosstour CR-V 2.4L 2008-2015. Please read our descriptions and pictur…

- 【Powerful Function】Our timing chain kits feature advanced design and vibration reduction technology to reduce friction a…

When to Seek Professional Help?

If the timing chain is stretched, timing marks are misaligned, or internal engine components show excessive wear, professional repair is strongly recommended. Incorrect timing repairs can lead to severe engine damage.

Can I drive with OBD2 code P0009?

Yes, but continued driving may worsen timing issues and cause engine damage over time.

What is the most common cause of P0009?

A stretched timing chain or incorrect camshaft timing is the most common cause, especially in high-mileage engines.

Does an oil change fix P0009?

In some cases, yes. Dirty or incorrect oil can affect VVT operation and trigger this code.